Hydrophobic Material for Venting and Filtration

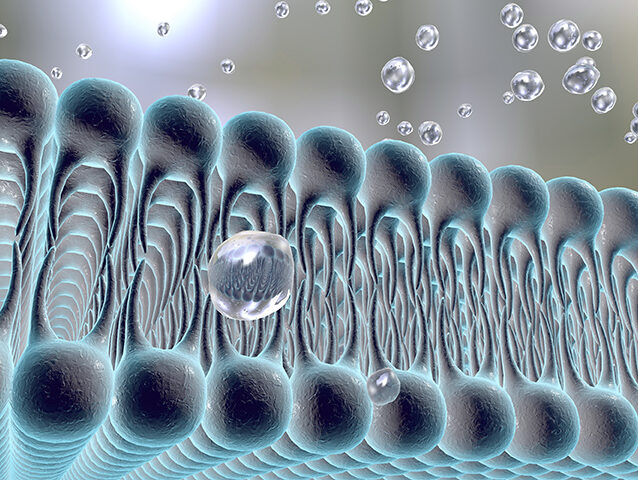

Hydrophobic materials repel water with low surface energy, allowing water molecules to shed contact with a solid surface, maintaining a contact angle of more than 90 degrees. This contact angle is also a measure of a material’s hydrophobicity. Porex’s hydrophobic material comes in a wide variety of polymer options that can be applied across multiple venting, filtration, and reflecting applications. These materials can be used as protection vents in electronics, automotive battery vents, sensor components, or anything that requires airflow and water resistance.

Talk with a Material Science Expert

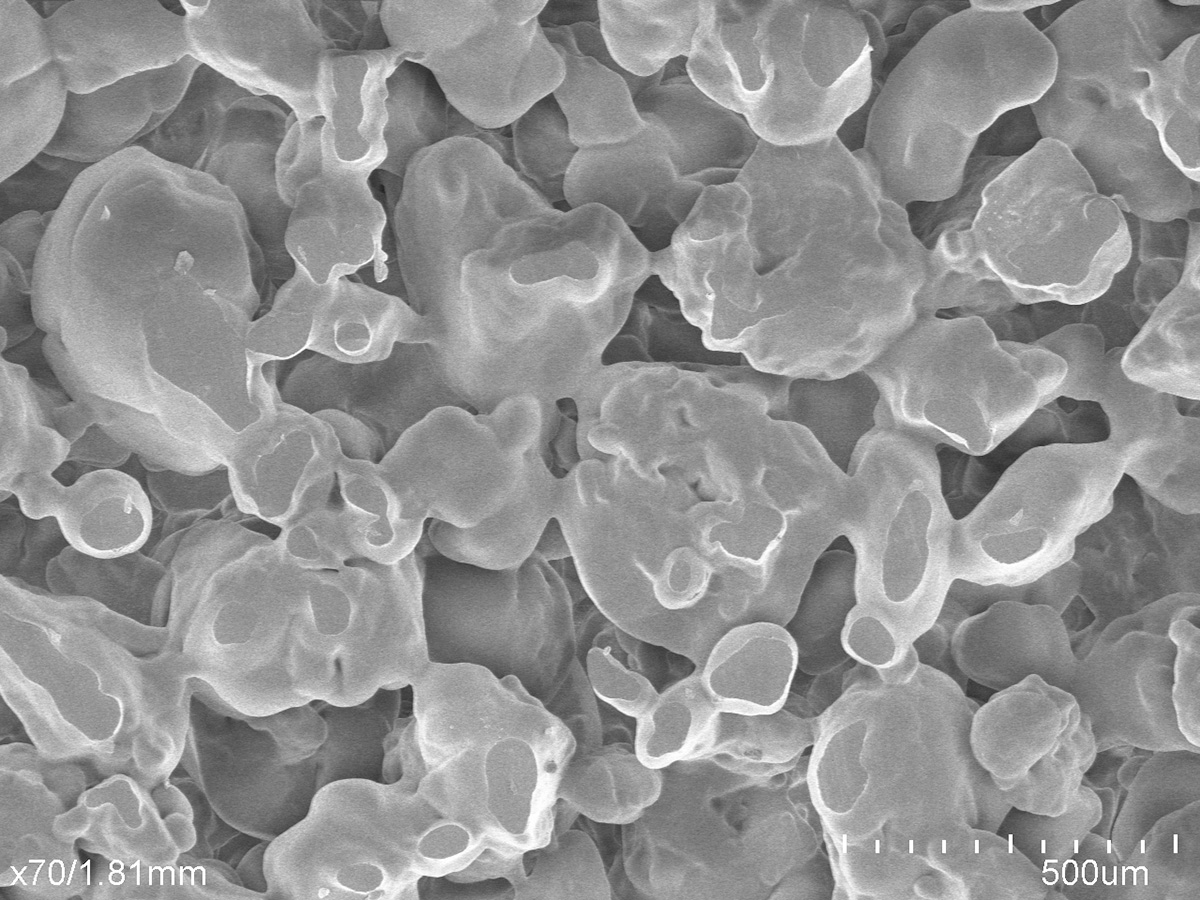

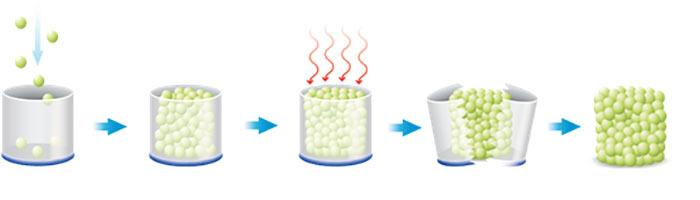

Hydrophobic material manufacturing process

Sintered polymers like polyethylene, polypropylene, polytetrafluoroethylene, and polyvinylidene fluoride are naturally hydrophobic with excellent water-repellent properties. These porous plastics are created by heating and applying pressure to fuse materials while preventing them from melting and maintaining their properties. This creates a porous medium that can be customized for your device’s performance needs, including optimizing pore size, pore volume, flow resistance, and filtration or venting capabilities.

Types of hydrophobic materials

Selecting the right material is paramount when designing hydrophobic porous plastics. At Porex, we understand that material choice directly impacts pore size, pore volume, operating temperature, chemical compatibility, and additive compatibility. As your innovation partner, we offer expertise and guidance to ensure you make informed decisions. We offer four different types of hydrophobic materials

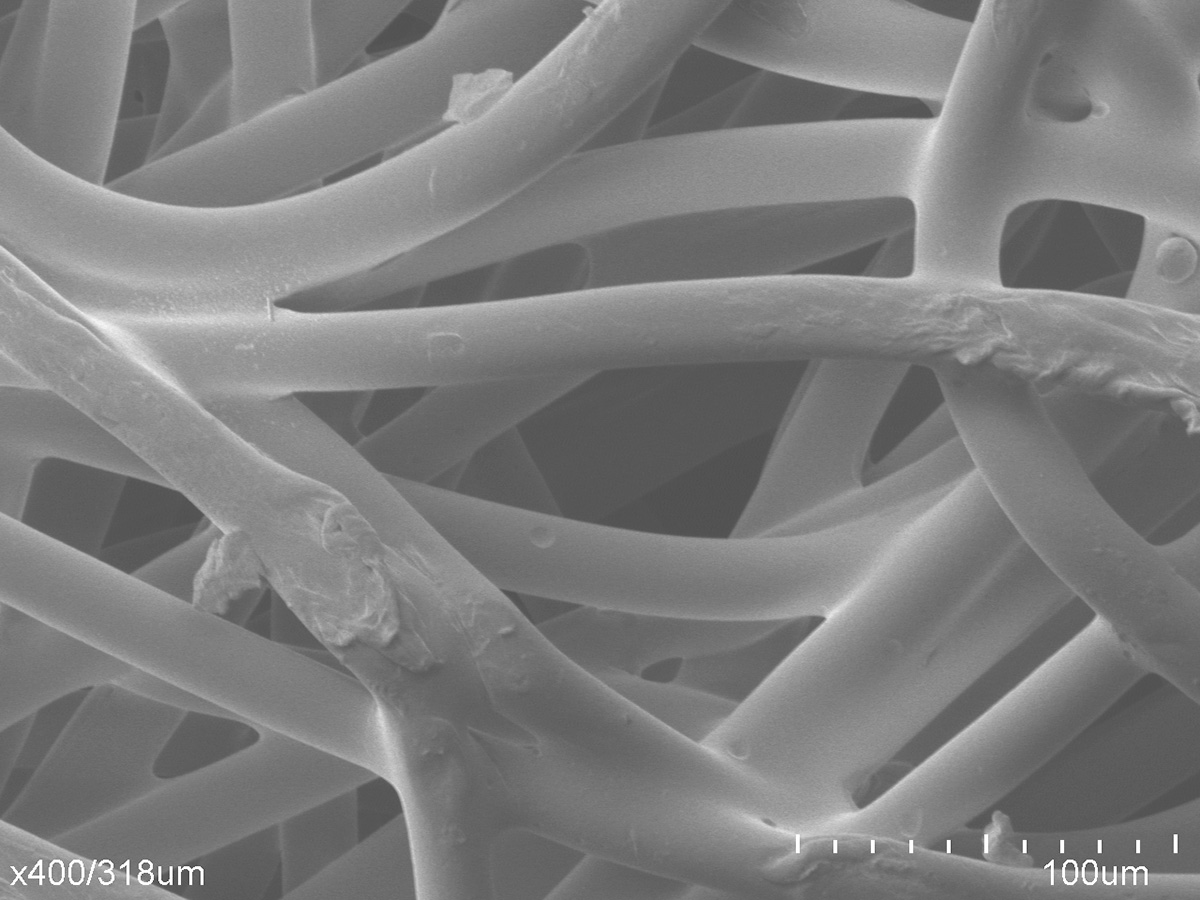

Polyethylene (PE) is widely used and offers pore sizes from 5 to 250 microns. This strong, lightweight thermoplastic is inherently hydrophobic and can withstand significant process variation. The next hydrophobic material, Polypropylene (PP), is ideal for applications requiring strength and larger pore sizes. PP shares chemical and additive compatibilities with PE and is naturally water-resistant. Next, Polytetrafluoroethylene (PTFE) is chemical resistant, durable, and ultra-hydrophobic. It’s pure, PFOA-free, excels in filtration down to 0.1 microns, and prevents fluid ingress. Lastly, Polyvinylidene Fluoride (PVDF) offers resistance to aggressive chemicals, extreme temperatures, and superior mechanical strength. Inherently hydrophobic, it’s an excellent choice for applications in harsh environments, electronics, and electrical engineering.

Porex is your partner in harnessing the full potential of these hydrophobic materials. Whether you need strength, chemical resistance, or ultra-hydrophobicity, our team of experts will assist you in selecting the ideal material for your project.

Warning: Undefined variable $accordion_tabs_content in /www/wwwroot/wordpress/wp-content/themes/FGC/template-parts/blocks/accordion-tabs/accordion-tabs.php on line 58

Common applications for hydrophobic materials

Filter

In the field of healthcare, sintered porous plastics can offer filtration capabilities that facilitate measured pharmaceutical delivery of inhalers, nebulizers, spray pumps, and other medical devices. In addition, they can be used to maintain the device’s sterility when utilizing antimicrobial additives.

Vent

This is one of the most common applications. Protective vents are used in many products, from electrical enclosures and container venting to medical devices and EV batteries. Our durable hydrophobic materials are the perfect option to support your needs.

Download our Technical Brief

Porosity Analysis on Hydrophobic Microporous Membranes

Related Resources

What Is Porous Plastic?

Read how porous plastic is formed as a component to control the flow of gases, liquids, light, or sound.

Understanding Pore Size Distribution

In this video, learn how to measure the space between the particles and it’s effect on component performance.

Understanding Pore Volume

Explore the impact of pore volume to better understand its impact on your device’s functionality.

Your Partner in Innovation

Discover how Porex has been a partner in innovation for over 60 years in this video.