Safer energy storage with porous safety vents

Optimize your energy storage and generation products by utilizing Porex porous components. With our unique and durable POREX Virtek® microporous PTFE membrane, the vent allows for general pressure compensation under normal use, and allows gases to escape rapidly in the event of product failure.

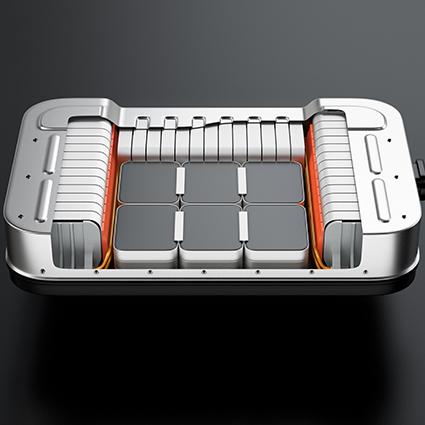

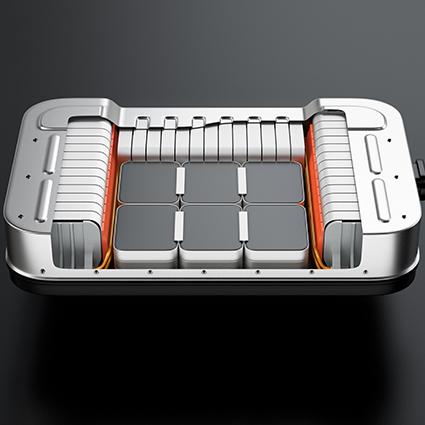

With a wide range of porous material technologies for various energy applications, Porex provides products such as membranes for separation of active portions of batteries, fuel cells, flow cells, and capacitors, fluid wicks and electrolyte support media to help keep your battery systems running smoothly.

Our safety vents for energy storage products:

- Can be customized to your application’s specific needs, including size and shape.

- Protect systems with versatile and optimized materials including POREX Virtek PTFE, sintered porous plastic, and breathable porous fiber.

Battery Protection Vents

Protect your battery systems with easy-to-attach vents

Separator Materials

Customizable porous materials meet your battery specifications

Fluid Reservoirs and Wicks

Control and retain fluids within energy storage devices

Battery Protection Vents

Protect your battery systems with easy-to-attach vents

As a leader in providing protection vents for batteries and battery systems, Porex offers a wide range of products – from standard sizes of adhesive protection vents, to finished vents within a housing that keeps batteries safe.

Available in a variety of materials, our protection vents:

- Attach easily to the battery system –Robust POREX Virtek PTFE structure can be attached using several manufacturing processes – including ultrasonic welding – and the membrane can also be mounted into an enclosure device for easy attachment.

- Are customizable with many material options including POREX Virtek PTFE, sintered particle polymer, breathable porous fiber

| POREX Virtek® PTFE Membrane Application Materials — Typical Properties | ||||||||

| Application Material | IP Rating † | WEP mbar | Airflow l/hr/cm² @70mbar | Filtration Efficiency** >99.99% | Thickness mm | Max Operating Temp °C | UL-94/746C* | Salt Fog |

|---|---|---|---|---|---|---|---|---|

| PMV10 | 64,67 | 270 | 125 | 0.5 µ | 0.13 | 260°C | V-0/f2 | No pen. |

| PMV10L*** | 64,67 | 270 | 85 | 0.5 µ | 0.3 | 100°C | – | No pen. |

| PMV15 | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | V-0/f2 | No pen. |

| ‡PMV15T | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | – | No pen. |

| PMV20 | 64,65,68 | 520 | 34 | 0.1 µ | 0.25 | 260°C | V-0/f2 | No pen. |

| PMV25 | 65,67,68 | 750 | 15 | 0.2 µ | 0.1 | 260°C | V-0/f2 | No pen. |

| PMV30 | 65,66,67,68 | 1000 | 4.5 | 0.1 µ | 0.25 | 260°C | V-0/f2 | No pen. |

| WEP = Water Entry Pressure RoHS, WEEE, REACH Compliant ** According to IEST RP-CC007.2 2009 ***Laminated polyolefin mesh backing † IEC std. 60529, IP 68 is a user defined test; will pass condition dependent ‡ Oleophobic Grade 8, AATCC TM 118 Properties are typical and not meant for specifications. Properties for membrane only, selected options and adhesives may affect properties. Testing results available upon request |

||||||||

| STOCK PRODUCT OFFERING – ADHESIVE DISCS | |||||

| Dimensions | Material Series | ||||

|---|---|---|---|---|---|

| OD/ID (mm)* | PMV10L | PMV15 | PMV20 | PMV30 |  |

| 7.0/3.0 (N) | PMV10LN | PMV15N | PMV20N | PMV30N | |

| 10.0/7.0 (I) | PMV10LI | PMV15I | PMV20I | PMV30I | |

| 12.7/7.1 (W) | PMV10LW | PMV15W | PMV20W | PMV30W | |

| 20.0/13.0 (C) | PMV10LC | PMV15C | PMV20C | PMV30C | |

| Dimensions | Material Series | |

|---|---|---|

| OD/ID (mm)* | PMV15 | Feature |

| 12.7/7.1 (W) | PMV15WH | High temperature adhesive |

| 12.7/7.1 (W) | PMV15TWH | Oleophobic with high temp adhesive |

| *1000 discs/roll N, I, W & C are size codes. Many other standard and custom sizes available. Contact Porex. |

||

| POREX Virtek PTFE Vent Plugs — Typical Properties | |||||||

| Part # | Diameter mm | Thickness mm | WEP mbar | IP Rating † | Vent Airflow l/hr/cm² @70mbar | Max Operating Temp °C | UL-94 Rating |

|---|---|---|---|---|---|---|---|

| PD103032 | 3.2 | 3 | 450 | 64,67,68 | 1 | 260°C | 5VA, f1 |

| Plugs meet UL-94 5VA and F1 rating. Assembly methods include: press fit, over-moulding, compression seal, or flange welding. |

|||||||

| Adhesive Vent Available Sizes | |

| Available Sizes | |

|---|---|

| OD (in mm) | ID (in mm) |

| 7 | 3 |

| 10 | 7 |

| 10.2 | 6.5 |

| 11 | 7 |

| 12.7 | 7.1 |

| 13 | 10 |

| 14.8 | 11 |

| 14.8 | 7 |

| 15.8 | 9 |

| 16 | 11 |

| 18 | 13 |

| 18.6 | 10.6 |

| 19.1 | 11.5 |

| 20 | 13 |

| 25.4 | 19 |

| 50 | 30 |

|

*Highlighted rows indicate stock items. Custom sizes available upon request |

|

Related Resources:

![]() Datasheet: POREX Virtek IP Rated Protection Vents

Datasheet: POREX Virtek IP Rated Protection Vents

![]() Datasheet: PTFE Fact Sheet

Datasheet: PTFE Fact Sheet

![]() Datasheet: Porex PTFE Ingress Protection Test Report

Datasheet: Porex PTFE Ingress Protection Test Report

![]() Demonstration Video: Hydrophobicity and handling properties: POREX Virtek PTFE vs. expanded PTFE

Demonstration Video: Hydrophobicity and handling properties: POREX Virtek PTFE vs. expanded PTFE

![]() Demonstration Video: Durability comparison of POREX Virtek PTFE vs. expanded PTFE

Demonstration Video: Durability comparison of POREX Virtek PTFE vs. expanded PTFE

![]() Demonstration Video: Dangers of not venting a sealed enclosure

Demonstration Video: Dangers of not venting a sealed enclosure

![]() Demonstration Video: Keep electronics dry and protected with POREX Virtek PTFE vents

Demonstration Video: Keep electronics dry and protected with POREX Virtek PTFE vents

![]() Demonstration Video: Demonstration Video: POREX Virtek PTFE vs ePTFE in a battery safety vent emergency situation

Demonstration Video: Demonstration Video: POREX Virtek PTFE vs ePTFE in a battery safety vent emergency situation

Separator Materials

Customizable porous materials meet your battery specifications

Separation materials from Porex can be used in batteries, fuel cells, flow cells and capacitors, and are available in POREX Virtek PTFE and various other materials. Their uniform porous structure combined with customizable pore volume and pore size ensure that the separator materials meet your battery’s specifications.

| POREX Virtek PTFE Membrane Application Materials — Typical Properties | ||||||||

| Application Material | IP Rating † | WEP mbar | Airflow l/hr/cm² @70mbar | Filtration Efficiency** >99.99% | Thickness mm | Max Operating Temp °C | UL-94/746C* | Salt Fog |

|---|---|---|---|---|---|---|---|---|

| PMV10 | 64,67 | 270 | 125 | 0.5 µ | 0.13 | 260°C | V-0/f2 | No pen. |

| PMV10L*** | 64,67 | 270 | 85 | 0.5 µ | 0.3 | 100°C | – | No pen. |

| PMV15 | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | V-0/f2 | No pen. |

| ‡PMV15T | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | – | No pen. |

| PMV20 | 64,65,68 | 520 | 34 | 0.1 µ | 0.25 | 260°C | V-0/f2 | No pen. |

| PMV25 | 65,67,68 | 750 | 15 | 0.2 µ | 0.1 | 260°C | V-0/f2 | No pen. |

| PMV30 | 65,66,67,68 | 1000 | 4.5 | 0.1 µ | 0.25 | 260°C | V-0/f2 | No pen. |

| WEP = Water Entry Pressure RoHS, WEEE, REACH Compliant ** According to IEST RP-CC007.2 2009 ***Laminated polyolefin mesh backing † IEC std. 60529, IP 68 is a user defined test; will pass condition dependent ‡ Oleophobic Grade 8, AATCC TM 118 Properties are typical and not meant for specifications. Properties for membrane only, selected options and adhesives may affect properties. Testing results available upon request |

||||||||

| POREX Virtek PTFE Vent Plugs — Typical Properties | |||||||

| Part # | Diameter mm | Thickness mm | WEP mbar | IP Rating † | Vent Airflow l/hr/cm² @70mbar | Max Operating Temp °C | UL-94 Rating |

|---|---|---|---|---|---|---|---|

| PD103032 | 3.2 | 3 | 450 | 64,67,68 | 1 | 260°C | 5VA, f1 |

| Plugs meet UL-94 5VA and F1 rating. Assembly methods include: press fit, over-moulding, compression seal, or flange welding. |

|||||||

Fluid Reservoirs and Wicks

Control and retain fluids within energy storage devices

Our POREX porous fiber media functions as an electrolyte reservoir that retains and can control and dispense fluids used in energy storage devices.

These reservoirs and wicks:

- Have very consistent densities and fluid transport capabilities

- Are customizable to your specific application

- Offer self-supporting properties that can be made into sheets or custom shapes and sizes to meet your device’s specific needs

Features

- Retain and deliver electrolyte fluids in energy storage devices

- Engineered for optimal density and fluid retention and transport

Materials Offered

- Porous polymeric fiber

- Sintered particle

Formats Available

- Sheet/roll format or 2D fiber shapes – can be self-supporting

- Customizable shapes and sizes based on application requirements